4 Steps to Take Your Concept from Paper to Prototype

At one point or another, everyone has had a bright idea. Likely, it all came together at an unlikely moment when all the moving parts suddenly snapped into place. After careful consideration, you’re probably wondering what your next steps are… or if there are next steps at all! Today, we’ll look at five easy steps you can take to turn your idea into a working prototype.

1. Determine if it’s viable

The first thing you need to do to determine if you have a viable product is to determine whether or not it is something that people will want. Does it solve a problem? Does it improve upon an existing product? If the answer to these questions is yes, then you’ve taken the first step towards making your prototype a reality.

2. Create a business plan

Now it’s time to get into the meat of your preparations: creating a business plan. At this stage, you should be asking yourself more than simple questions. Often, difficult questions lead to profitable avenues… does your product have alternate uses? Can it be repurposed to serve a wider market?

3. Start designing

Once you’ve got the idea refined, organized and fully developed, you should begin fleshing out the physical design of your prototype. This step can be difficult for many creators, as it requires a highly technical mind and complex analysis software. At Protomatic, we understand the importance of this step and offer prospective creators a wealth of design services. One of our most valuable tools, Design Failure Effects Mode Analysis, lets us analyze potential failure modes of your product’s functionality.

4. Begin manufacturing

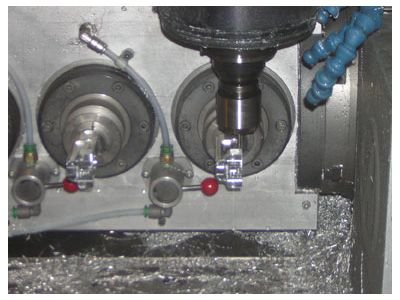

At the manufacturing stage, your idea is finally starting to become a reality. Unfortunately, this step presents whole list of new complications. At Protomatic, we provide Process Failure Effects Mode Analysis. While similar in concept to the tool used during the design step, this tool allows us to know what could go awry during the manufacturing process. From this information, we can offer suggestions in regards to materials, treatments and processes.

Here at Protomatic, we aim to provide a range of services that allow you to take your product concepts from paper to prototype. As a CNC contract manufacturer, we have the experience and equipment necessary to develop your product. From aerospace to medical components, we invest ourselves into every project, delivering the best possible results. If you’d like to read more about prototyping, we invite you to take a look at, “How to get your idea turned into a prototype,” in our Downloads section or, of course, you could reach out to one of our knowledgeable employees.