Life-saving precision up close.

“To make good parts, we must be able to see them,” stated Doug Wetzel, General Manager at Protomatic, Inc. He added, “We need to see the parts up close, very close.”

Precision requires a microscopic point of view.

Our equipment and tools are designed to “cut metal” which means shaving off 0.001-0.005 inches with every cutting edge. The human eye simply can’t register measurements that miniscule. But a microscope can.

Here’s why Protomatic feels microscopes are so vitally important. If a cutting tool becomes dull it will have a tendency to “smear” or “plow” the metal instead of cutting it. This causes varying surface finishes and sub-surface stresses that will only show up after the part is anodized or plated.

We use sophisticated, high-magnification microscopes to inspect the wear on the tools we are using, as well as the final part surfaces. The microscopes also allow us to confirm that even the tiniest part has been deburred correctly.

As an integral part of our quality control process, microscopes allow our machinists to continually produce parts that meet the most demanding tolerances.

Let’s put an uncoated aluminum part under the microscope.

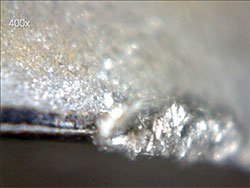

This flaw at 400x magnification shows a variation in the surface finish from a single tool feed line before the part was hard coated. The rough surface resulted from a plowing action caused by a change in the tool geometry when a coating was added to improve tool life and part-dimensional control. This was not visible with an unaided eye because it was aluminum and the metal smear does not contrast (silver on silver) when the finish has a surface finish of Ra 4 (almost mirror like).

Hard-coated aluminum at 400x magnification

This photo shows the result of the poor chip formation. At 400x magnification, the raised flaws in white show up with high contrast against the black background of the freshly hard-coated part. Although microscopic, this flaw may have had a profound impact on the performance of our customer’s application, had it gone undetected.

Take a look at what aluminum build-up on a cutting edge can do to a carbide insert.

This 400x magnification photo is the used cutting edge of a coated tool. The lump of metal on the right side causes poor chip formation and will plow the metal surface. The left side of the photo shows a clean cutting edge that will leave the consistent surface finish needed for good secondary operations.

Optical Microscopes

Obviously, not all microscopes are the same quality. Protomatic has learned that “special deal” microscopes do not always have adequate resolution, and are in fact, useless in the shop. The sharp resolution we require can only be attained with high-quality optics. No matter how well a machinist programs tool paths to prevent burrs on freshly cut medical parts, fine feathery burrs will still be present in cross holes of 0.005-inch diameter. Because we take the time to meticulously examine every part we make for you, you can be assured that it has been deburred properly.

Keyence 3D Microscope VHX-2000E

Keyence 3D Microscope, with additional gooseneck lighting system. This microscope system has high-resolution digital cameras, motorized X, Y, and Z stage and measurement capability.

There are many examples where we have seen the benefits of a microscopic look. Often, the problem or improvement cannot be seen with the naked eye, but a magnification easily brings the issue into focus. At Protomatic, we are typically looking at parts with a 20-50x power. Sometimes we need 100-200x to examine drills, end mills, carbide inserts and metal surfaces. To identify subtle surface finishes and tool/chip action, we will use 400x magnification or more.

We have equipment from Nikon and Keyence Vision Systems utilizing magnification from 1x to 200x, optical comparators 10-20x, 3D microscopes 5-50x, and profilometers and surface analyzers (Tally Surf) that measure in thousands of microns. Of course, the microscopes are only as good as the people who use them. We feel our staff is second to none in using microscopes to understand and improve the manufacturing processes.

Freedom Scientific HDMag™ Inspection Station

Some microscope applications require quick visual inspection. This High-Magnification Inspection Station HDMag™ offers 2x-50x with autofocus and video, and greatly improves old watch glass inspection.

Showing the Way

We work closely with our customers and use microphotographs to answer questions about specific features or transition areas. We often show our customers features or details about their parts they never knew were critical to their functional performance. Educated customers are the best customers, and we strive to help them every day.