Parts Inspection: Is Your CNC Machine Shop Cost Effective?

One of the most critical aspects in choosing CNC machine shop is the method it uses to inspect the parts they produce. It is important that you understand the different methods used by CNC shops and what they mean to product performance and quality.

This article will give you an overview of various types of parts inspection and the effect they have on economics and cost.

AQL (Accepted Quality Limit) Sampling

One of the most widely used techniques in parts inspection is AQL sampling. Sampling a representative selection of parts is an easy way to gauge the quality of the entire run. There are several distinct advantages to product quality sampling, including:

- Reduced cost, because not every part is inspected

- Less opportunity for product damage

- Lower labor costs due to fewer inspection personnel

- Less monotonous for the inspector, leading to better job performance

- Allows for lot-by-lot examination

- Applicable for destructive testing

100% Inspection

With 100% inspection, every single part is reviewed. At first glance, this may seem like the best possible inspection method, but there are some disadvantages to inspecting each and every part:

- 100% inspection does not guarantee 100% compliance

- Very expensive to inspect all parts

- More opportunity for product damage due to increased handling

- Increased cost for inspection personnel

- 100% inspection is monotonous for the inspector, and may lead to reduced performance

- Requires complete lot examination

- Cannot perform destructive testing

No Inspection

While not a very smart option, this is indeed still an option. If you get lucky, you can skate through without a problem. But if there are defects, it will cost more to correct them, plus you will have lost valuable time because the problem wasn’t identified earlier.

OK. Which method is most cost effective?

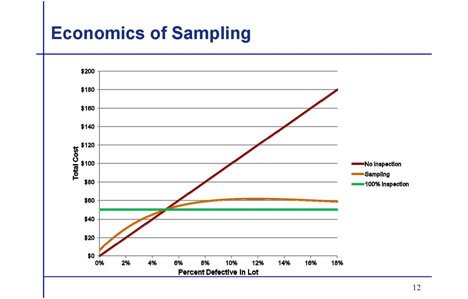

This is where the rubber meets the road. What are we looking at in the way of cost? For the purposes of this example, we’ll compare conditions for a typical inspection.

To prepare calculations we have to make a few assumptions, please adjust for your product conditions.

- Lot Size: 100-piece lot

- Sampling Plan: C=0 with a sample size of 13 pieces

- Acceptance Quality Limit (AQL- probability of accepting a bad part in the lot as a percentage, at a certain confidence level) = 1.5 ( 1.5% pass/fail criteria probability)

- Cost of inspection: $0.50

- Cost of a defect: $10.00 (This is the cost if a defect isn’t caught, or in other words, is the cost to fix the higher assembly if a defective part is used.)

Graphing as a percent defective, shows that:

- 100% inspection — a fixed cost for the lot.

- No Inspection — costs are related to the quantity that is defective in the lot. The cost has increased the risk with a higher defect rate. This is a linear relationship. More defective parts will cost more to process the repair.

- Sampling Inspection (AQL) — a blend of 100% inspection and no inspection. The example required a 13% sample. This cost is related to the initial cost of inspecting the sample of 13 pieces and possible undetected defects in the lot, based on the acceptance at a confidence level of the AQL sample. Detection of a failure in the sample would reject the entire lot. But, if missed in the sample, the possibility of accepting a lot could occur, because 87% of the lot was not inspected.

Inspection methods are just one of the many considerations when choosing a CNC machine shop. For a complete list of things to look for, please download the free guide, Tips for Choosing a Prototyping Machine Shop.

Many of the thoughts in this article came from a document titled “Advantages and Disadvantages of Sampling,” by Jeffrey S. Solomon.

About the author: Doug Wetzel is Vice President and General Manager of Protomatic. Protomatic is a CNC precision machining shop specializing in prototype and short-run production components for the medical, aerospace and other technical industries. Because of the critical nature of the parts they design and manufacture, the emphasis is always on Life-Saving Precision.