Protomatic Adds Microscopic Contour Inspection Capability

Measuring texture, form and contour simultaneously on the inside of complex surfaces was next to impossible without destructive sectioning (cutting the part in half) a sample part and inspecting with an optical comparator.

So this month, Protomatic added a “Tally Surf” unit to help measure complex internal and external profiles non-destructively for critical medical and aerospace applications.

With the Taylor-Hobson Form Talysurf Intra, you can be assured that we have manufactured your desired surface, no matter how geometrically complex or texture sensitive. The Taylor-Hobson Form Talysurf may look like a typical profilometer, but only on the surface. This equipment enables us to confidently verify the contour and surface finish of your parts with extreme precision.

The “Tally Surf” has measuring capabilities that go far beyond what is possible with Coordinate Measurement Machines (CMM), Vision system and Optical Comparators. Part surfaces having even the most subtle finishing differences will be accurately measured.

Taylor-Hobson Form Talysurf Intra unit.

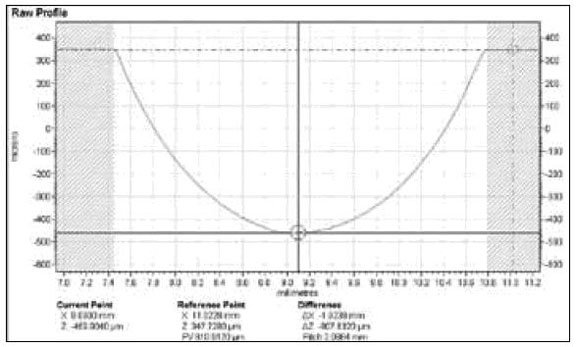

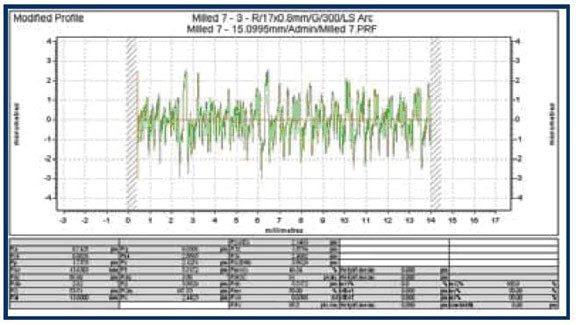

The real accomplishments take place using an inductive pickup probe feeding advanced software. By precisely measuring the actual part to the theoretical or programmed machine tool paths, we can define our machining accuracy by assessing form error with a best-fit analysis. We can describe the microscopic variations to the actual request, enabling us to recognize the accuracy of the parts we make.

Contour chart

Surface finish profile printout

All parts, no matter who makes them, have a tolerance range for the machinist to work within. These ranges get smaller each day, it seems. Our customers are a specialized group and very demanding about this high accuracy – rightfully so, due to the applications. The parts we make for them are usually Mission Critical, meaning that we must deliver parts that function properly on the first try. This is what we call here at Protomatic, “Life-Saving Precision.”

Our customers are always pushing us to push the envelope of machining precision and technology. We strive to deliver the leading edge support for them every day.