Protomatic Brings Precision to Preventive Maintenance

Preventive maintenance of CNC machines is critical to manufacturing parts for the medical and aerospace industries. Because of the typical age/wear of our machines, we ensure that they are validated for accuracy on a regular basis.

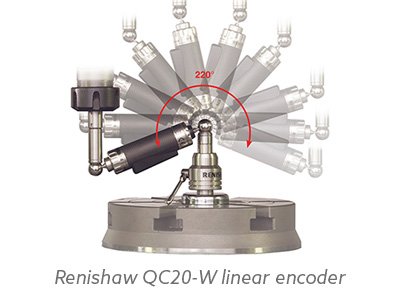

One of our most important methods of verifying machine accuracy is through our use of the Renishaw Ball Bar Tester, model QC-20W.

What the Renishaw ball bar tester measures

The Renishaw QC20-W transmits the distance between two mounting balls when the CNC machine is programmed to produce an ideal circle. It measures in all planes, X-Y, Z-X, and Y-X. This enables us to confirm the CNC machine’s operational and I/O performance by measuring positional performance.

How accuracy is improved

We set the Renishaw tester to measure the Z-X performance of a typical CNC VMC. We want it to show Counterclockwise and Clockwise measurements when the machine was programmed for an idea circle at 50ipm. The result should be a perfect circle. When it isn’t, we correct the lateral play, squareness, lead screw backlash or other properties of the machine.

This graph below shows a measurement of a corrected machine in the scale of 0.0005”. It originally demonstrated a circularity error of 0.0041”. Adjustments improved overall machine accuracy and it now has an error of only 0.00053”. This is a significant performance improvement which translates into much better part accuracy for our customers.

Verification is a never-ending process

Due to age (wear) of machines or accidental overloading, machines must be verified regularly. Along with using the Renishaw Ball Bar Tester, Protomatic measures and evaluates with Renishaw software to help identify causes of machine errors. This information helps us systematically correct and improve each machine, so they produce at optimum performance levels.

Different measurements take different tools

Measurements with the Renishaw Ball Bar Tester QC20-W are very small with a resolution of 0.1 micron. However, circularity error is only one measurement, and the values do not always relate to ball screw linearity or machine errors. Protomatic also identifies CNC errors using our CMMs and high-resolution vision systems. Other tools include precision levels, laser interferometers and rotary encoders.

Protomatic measures up

Protomatic is a CNC precision machining shop specializing in prototype and short-run production components for the medical, aerospace and other technical industries. We are committed to providing our customers with parts and devices made to the highest levels of accuracy to result in Life-saving Precision.

CONTACT US DIRECTLY. Phone 734-426-3655

- Scott Allen, Sales Manager Scott@Protomatic.com

- Lori Franz, Sales Lori@Protomatic.com

- Doug Wetzel, VP/GM Doug@protomatic.com

- Brian Heldt, Program Manager Bheldt@protomatic.com

About the author: Doug Wetzel is Vice President and General Manager of Protomatic.